Wuqiang Jinheng Trading Co., Ltd.

What technologies are used to treat oil leakage in power transformers?

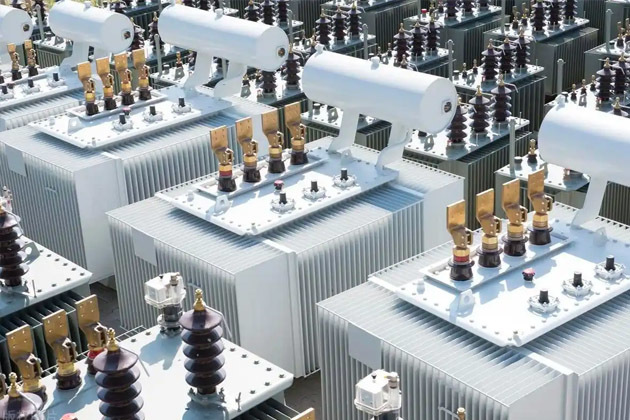

Transformers are one of the key electrical devices in distribution stations. They are widely used to solve the problems of heat pipe heat dissipation in large Spaces and insulation at high working voltages of transformers. However, the common problem of oil leakage in oil-immersed transformers during operation seriously endangers the safe operation of the transformers. What technologies are used to treat oil leakage in power transformers? Let's take a look together ~

Welding repair technology

For oil leakage in parts such as transformer boxes caused by cracks at welding points, welding repair methods can be adopted. First, the oil stains on the oil leakage area should be cleaned thoroughly to avoid defects such as pores during welding. Then, based on the material of the box body (such as common steel, etc.), select the appropriate welding process, such as manual arc welding, gas shielded welding, etc. If it is a small crack, spot welding can be used for gradual repair. For larger areas of damage, continuous welding should be carried out. However, during the welding process, it is necessary to pay attention to controlling the welding heat to prevent thermal damage to the insulation and other components inside the transformer, and at the same time, take good safety measures such as fire prevention.

Sealant sealing technology

Often, the oil leakage of transformers is caused by the failure of sealing parts, such as the aging and damage of sealing gaskets. At this point, high-quality sealant can be used for sealing treatment. First, remove the old sealing gasket at the oil leakage point, clean the sealing surface thoroughly to ensure it is flat, free of oil stains and impurities. Then, select an appropriate sealant, such as silicone rubber sealant with good oil resistance, high-temperature resistance and aging resistance, and apply it evenly on the sealing surface. Install a new sealing gasket and make the sealing surface closely adhere by tightening bolts or other means to achieve a good sealing effect. Prevent oil leakage.

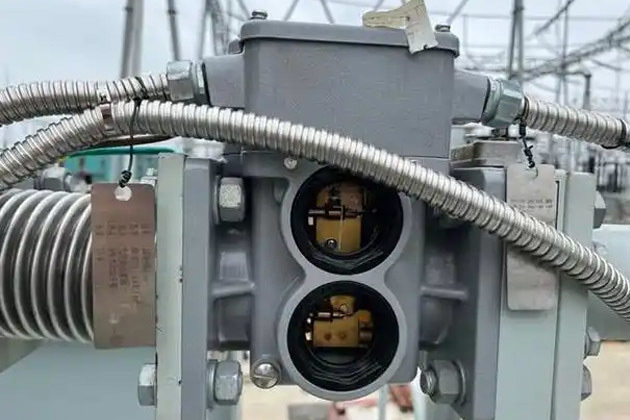

Pressure-sealing leak sealing technology

When the transformer is in operation and cannot be immediately shut down for maintenance, pressure-sealing technology can be adopted. This technology utilizes special leak-stopping tools and sealing materials to seal the leakage points under the pressure of the transformer. For instance, when using the pressure-sealing method of injecting sealant, a special fixture is first fixed around the leakage area to form a sealed cavity. Then, the sealant is injected into the cavity, which fills the leakage channel under pressure to achieve the sealing. However, this technology requires professional operation and must be carried out strictly in accordance with the operating procedures to ensure safety and the effect of leak sealing.

Fastening bolt treatment technology

Sometimes, due to long-term operation, the bolts at the connection points of the transformer become loose, resulting in poor sealing and oil leakage. At this point, the bolts at the relevant parts can be inspected. For loose bolts, use an appropriate torque wrench to tighten them according to the specified torque to ensure that the connection parts fit tightly and restore good sealing performance. At the same time, check whether the threads of the bolts are damaged or not. If any damage is found, replace the bolts in time to prevent oil leakage from happening again.

Hot Tags:

PREVIOUS:

NEXT:

Contact Us

Tel:

Phone/Wechat:

WhatsApp:

Email:

Add:

Wuqiang County HengShui City Hebei Provinice China